Alfatherm Insulation, a leading name in the insulation industry, proudly presents its revolutionary Bubble Insulation Solutions. Designed to redefine thermal performance and energy efficiency, Alfatherm’s Bubble Insulation is the answer to creating environments that are comfortable, sustainable, and cost-effective.

AEROLAM Group of Companies have diversified Business interests in Real Estate, Building & Construction, Education, Manufacturing, Packaging and Plastic Films. The Group boasts of cutting-edge technology, highly skilled professionals & top-quality products.

The AEROLAM Group of Companies comprises of leading professionals, high quality and precisely designed products, through high-end engineering and advanced R&D. AEROLAM Promoters with their humble team had a vision, which successfully culminated in the inception of AEROLAM Insulations Pvt Ltd in 2011. A purposeful market research with a clear and focused approach to understanding the need for insulation products has been a crucial factor in their growth. The need to manufacture and market products which are unique and challenging has taken the company a notch higher in the industry.

AEROLAM being pioneer in the Double Bubble Insulation Reflective insulation in the Indian market. Has also installed the first machine in the world to manufacture double bubble, bubble guard boards. AEROLAM today in real sense is a multifaceted Organization with manufacturing prowess in Reflective Insulation Material, XLPE (Chemically cross-linked closed cell polyethylene foam) Insulation Material, FIBC (PP Woven jumbo Bags), PP Bubble Guard Board (a board with endless applications and seamless possibilities) & CPP Film (Especially for Medical & Food grade Packaging).

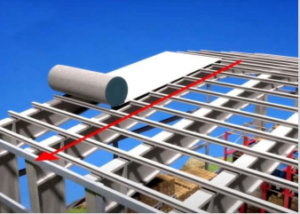

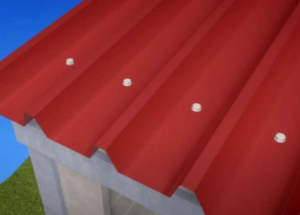

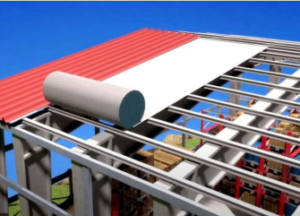

BUBBLE: AEROLAM is the first manufacturer in India to produce double Bubble Insulation Sheets In Delhi and the first to have a state-of-the-art extrusion lamination technology of its kind. AEROLAM manufactures insulation of various thicknesses, starting from 4 mm up to 20 mm.

XLPE: AEROLAM XLPE is manufactured using world-class manufacturing equipments and facilities, capable of manufacturing products in line with the highest international standards. Highest quality raw materials, practices and quality management systems enable AEROLAM XLPE to deliver the best quality end-product.

BUBBLE GUARD: A multi-layer alveolar board made from 100% polypropylene with a unique circular honeycomb structure core at the centre and two flat surfaces on either side with great versatility and high performance. It is 100% eco-friendly & recyclable.

CPP FILM: AEROLAM Closures has developed high performing metallisable CPP and CPE structures, making it possible to replace met-PET in multi-material packaging; for this purpose, AEROLAM Closures has also invested in the newest Bobst metallising unit.